Steam Lagging & Boiler Thermography

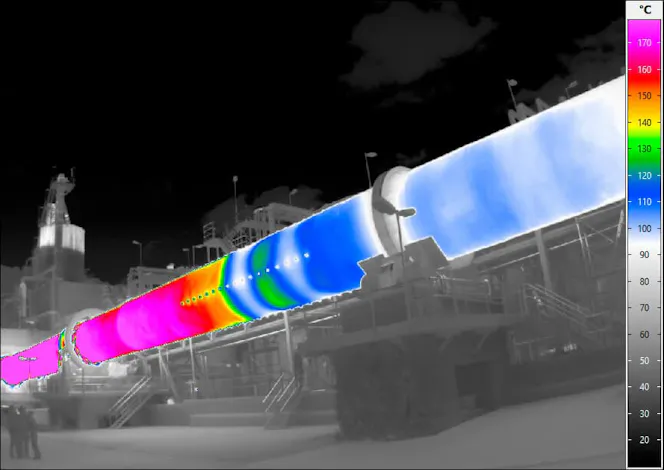

Industrial thermographic inspection of boilers, furnaces, steam lines, lagging insulation, and high-temperature process equipment. Identify insulation breakdown, refractory failure, and measurable thermal energy loss under ISO 18434 and ISO 50001 methodologies.

Services List

Downloads

Thermal Loss Diagnostics for Boilers, Furnaces & Steam Systems

Industrial boilers, furnaces, steam lines, and heat-transfer systems operate under extreme temperatures. When insulation or refractory materials fail, the resulting thermal losses directly increase fuel consumption, degrade system efficiency, and introduce serious safety risks.

Enisave Solutions performs detailed thermographic imaging on steam lagging, boiler shells, high-temperature piping, heat exchangers, and furnace casings. Each survey follows **ISO 18434-1 (Thermography for Condition Monitoring)** and **ISO 50001 (Energy Management)** methodologies to quantify heat loss and prioritise corrective maintenance.

Systems We Inspect

- Steam lines (main distribution & process feed)

- Boiler shells, doors, expansion joints & manways

- Furnaces, CAB units, flux driers, refractory casings

- Condensate return lines & heat exchangers

- Valves, flanges, traps & steam fittings

- Insulation lagging (mineral wool, calcium silicate, ceramic fibre)

Common Defects Identified

- Insulation saturation or missing lagging

- Refractory breakdown / furnace wall hotspots

- Steam leaks, gasket failure & flange losses

- Poor insulation thickness / degraded cladding

- Heat loss through boiler seams & access doors

- Damaged or corroded pipe lagging

Why Thermography for Steam Systems?

Steam distribution and boiler systems lose significant energy due to insulation defects. A single metre of uninsulated 150°C pipe can waste up to:

- **850–1,200 W/m of continuous heat loss**

- **R 400–R 1,200 per month per defect**, depending on fuel type

Thermal imaging quantifies these losses without shutting down production, enabling targeted insulation repairs where the ROI is highest.

Energy Loss Calculation Method

Enisave applies the **ISO 50001 Option B estimation method**, including:

- Surface temperature measurement

- Ambient reference temperature

- Emissivity modelling

- Heat transfer coefficient estimation

This enables approximate kW loss, annual energy waste, and financial impact calculation.

Compliance & Standards

- ISO 18434-1 – Mechanical & thermal condition monitoring

- ISO 50001 – Energy management and efficiency

- SANS 10177 – Thermal insulation material behaviour

- SANS 204 – Energy-efficient building thermal systems

Survey Deliverables

- Thermal + visible imaging of defects

- Surface temperature mapping & hotspots

- Estimated heat-loss (kW) for major anomalies

- Financial impact estimation (annual cost)

- Corrective recommendations & insulation specs

- Insurer-ready PDF reporting

Industry Applications

- Food & beverage processing

- Manufacturing & industrial steam plants

- Sugar mills & paper mills

- Marine boiler & steam systems

- Chemical & refinery environments

Book a Steam Lagging / Boiler Survey

Enisave Solutions provides professional thermal-loss assessments nationwide, helping clients reduce fuel consumption, extend boiler life, and optimise energy efficiency.